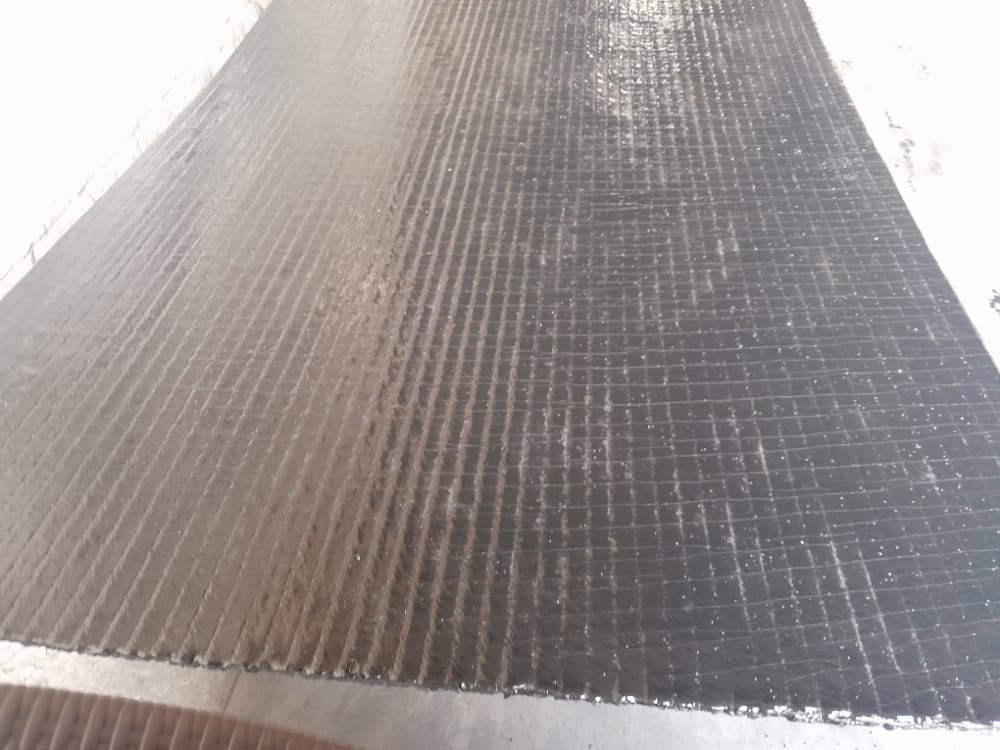

BURAK (CCO) WEAR PLATE, produced by using a mild steel base plate and hard-faced/overlayed by open arc welding, preferably High chromium welding wire. The structural steel (MS) is hard-faced with alloys for wear protection by abrasion, erosion, corrosion, and impact. The wear plate can be formed and rolled. Also Wear Plate can be welded, bolted or studded to the existing structures for wear protection.

Cost-effective solution when compared to traditional abrasion-resistant steels

BURAK ( CCO ) Wear Plate, Recommended for resistance to wear by abrasion, particle erosion in high-temperature applications.

It can be cut by Plasma, air arc, and water jet. Also can be joined by welding, using 309/312 weld wire/rod, plate rolling should be in the direction of weld beads.

BURAK 600 CCO wear plate.

Suitable for Abrasion and low to moderate impact

BURAK® 600 Chromium carbide overlay (CCO) wear resistance plate is a composite Wear Plate produced by open arc welding from flux-cored hard facing wires. It is suited for application high abrasion and low to moderate impacts, such as shutes, ducts ....etc

Chemical, C, Cr , Fe

Hardness 58-62 HRC

Heat resistance < 400 c

Cladding Area 1300*2800 mm

Thickness 5+3,6+4,8+6,10+8 etc

Industry Mining, glass industry, cement plant, steel mill, power plant, etc

Base Metal Structure steel

Chemical Composition(%)

C Cr Mn Si Fe Other

3.0-5.0 15.0-35.0 1.0-3.0 1.0-3.0 Bal.

BURAK 650 CCO wear plate.

Suitable for High Abrasion and moderate impact

BURAK® 650 Chromium carbide Overlay (CCO) wear resistance plate is a composite Wear Plate produced by open arc welding from flux-cored hard facing wires. It is suited for application high abrasion and low to moderate impacts, such as buckets, hoppers, chutes ...etc

Chemical, C, Cr , Fe

Hardness 58-65 HRC

Heat resistance < 450 c

Cladding Area 1300*2800 mm

Thickness 5+3,6+4,8+6,10+8 etc

Industry Mining, glass industry, cement plant, steel mill, power plant, etc

Base Metal Structure steel

Chemical Composition(%)

C Cr Mn Si Fe Other

3.0-5.0 25.0-45.0 1.0-3.0 1.0-3.0 Bal.

BURAK 700 CCO wear plate.

Suitable for severe Abrasion and moderate impact

BURAK® 700 Complex carbide overlay (CCO ) wears resistance plate is a composite Wear Plate produced by open arc welding from flux-cored hard facing wires. It is suited for application high abrasion and low to moderate impacts, Such as liners, ducts, chutes, impellers,.... etc.

Chemical, C, Cr, Nb, Fe

Hardness 57-63 HRC

Heat resistance < 550 c

Cladding Area 1300*2800 mm

Thickness 5+3,6+4,8+6,10+8 etc

Industry Mining, glass industry, cement plant, steel mill, power plant, etc

Base Metal Structure steel

Chemical Composition(%)

C Cr Mo Mn Nb. Si Fe Other

4.0-6.0 20.0-28.0 0.3-0.1 0.5-2.5 3-4.5 0.5-2.5 Bal. ----

-

BURAK 750 CCO wear plate.

Suitable for high Abrasion with high temperature

BURAK® 750 Complex carbide overlay (CCO) wear resistance plate is a composite Wear Plate produced by open arc welding from flux-cored hard facing wires. It is suited for application high abrasion with high temperature. Such as exhaust fan blades, clinker cooler plates, screens, chutes, etc

Chemical , C, Cr ,Nb,V,W, Mo

Hardness 62-65 HRC

Heat resistance < 650 c

Cladding Area 1300*2800 mm

Thickness 6+4,8+6,10+8 etc

Industry Mining, glass industry, cement plant, steel mill, power plant, etc

Base Metal Structure steel

Chemical Composition(%)

-C V W Cr Nb Mo

4.0-6.0 0.8-1.2 1.8-2.2 22.0-25.0 5.0-7.0 5.0-7.0