We ( AHE ) are the pioneer in rebuilding job of press rollers in Pakistan . Since 2007 , we are doing this job and we have rebuilded more than 130 rollers press of cement “OR” Raw mill area , in Pakistan till 2020 with more than satisfactory results .

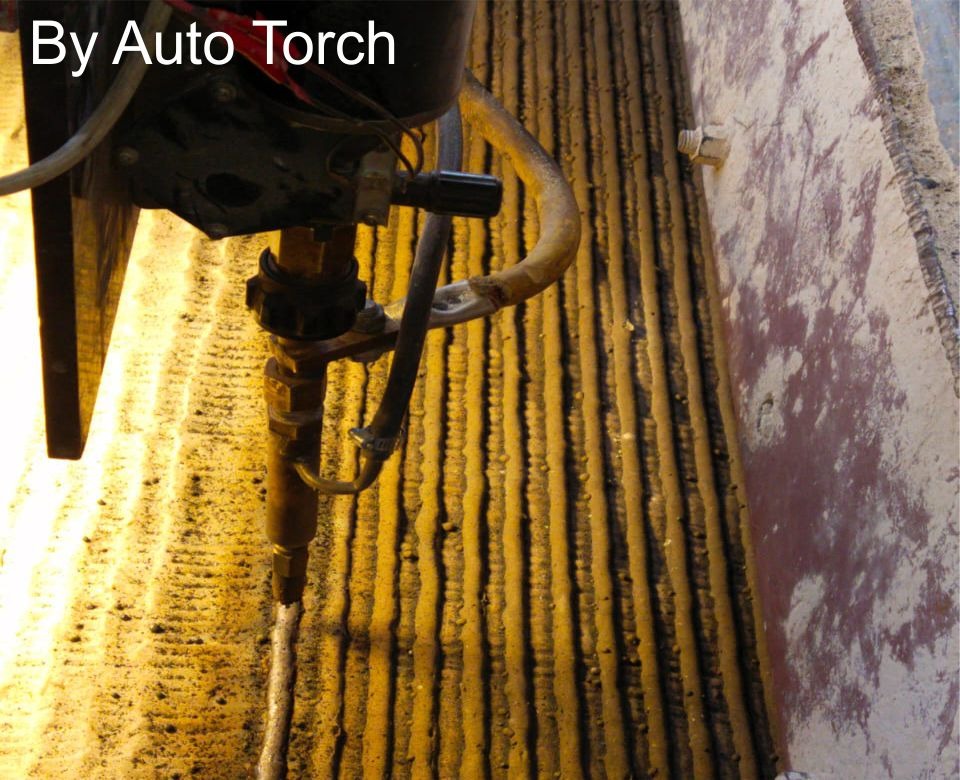

For the repair of entire damage surface , the repaire of intire roller surface could be perform at “ON site welding “ also called “in situ welding “ and at “workshop welding “.

Thanks to Mr. Peter ( CEO of CERTILAS , HOLLAND ) for his assistance in this regard .

Gouging the first defective area to remove off damage hard facing and by Hand Grinder “Or” auto grinder clean up the gouged area . Before starting welding , we will preheate the roller till 80 to 100C for removing moisture from roller’s surface .

Following are the three main factors for rebuilding press rollers,

1, Proper welding consumable ( 34%)

2, Proper welding Equipments (33%)

3, Proper welding technique (33%)

1, In situ