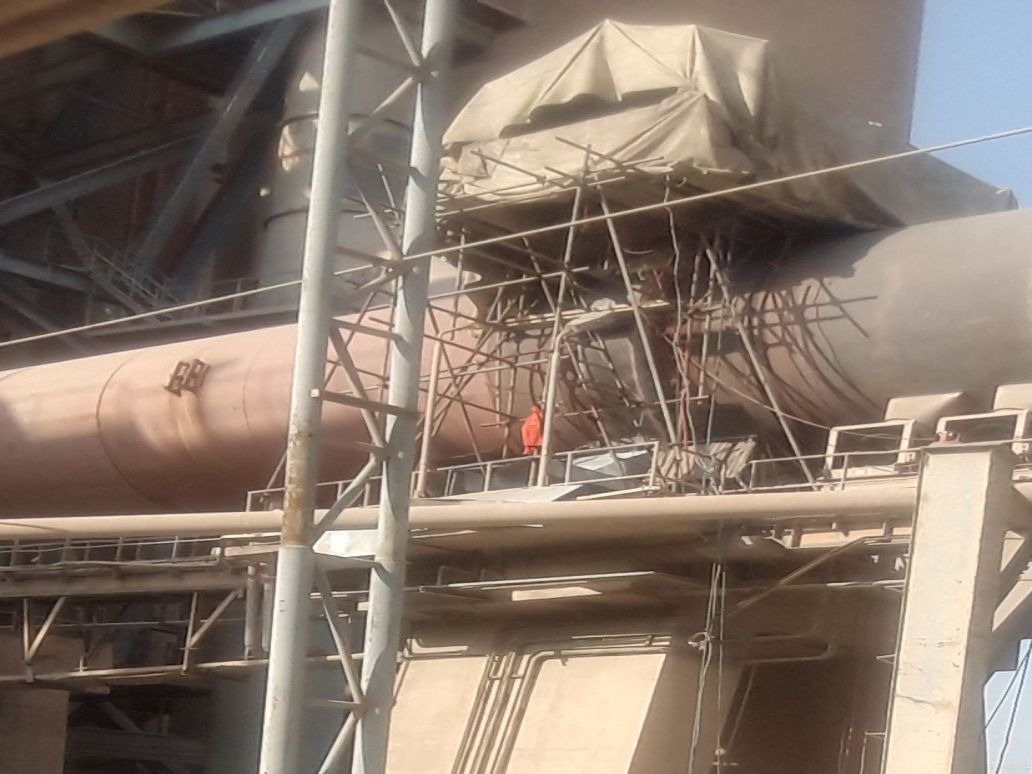

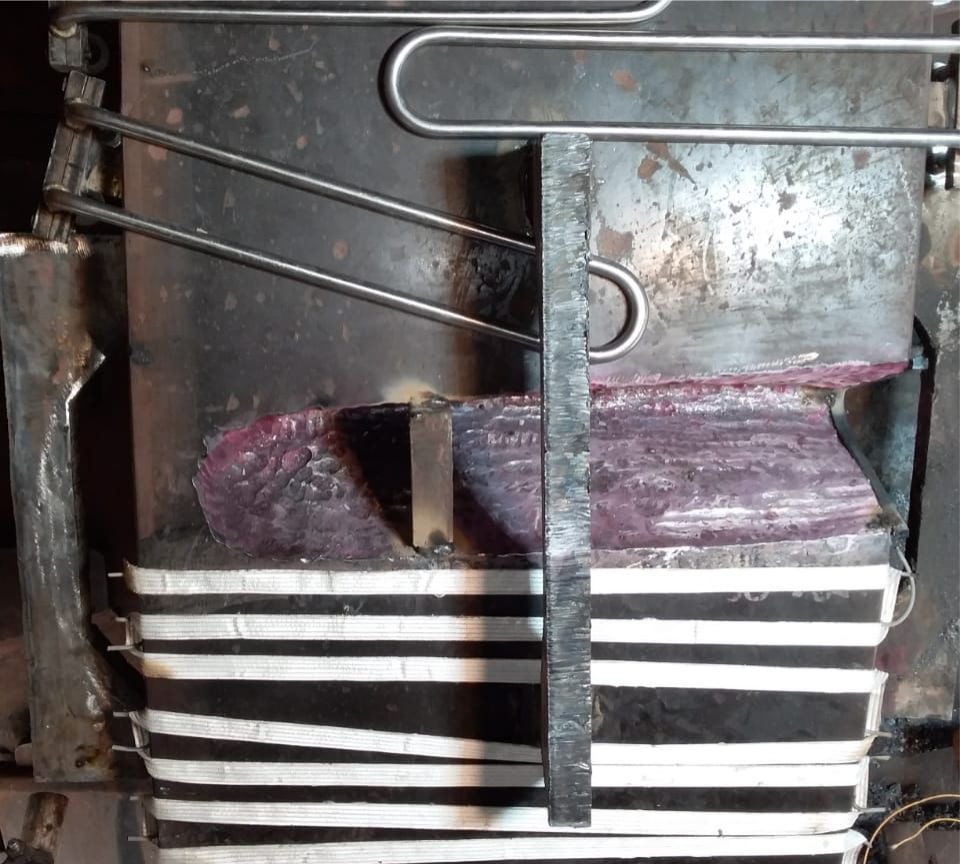

Crack Repair Job On Kiln Tyre

Crack formation in the kiln tyre is a well-known phenomenon. The reason of crack formation is

mechanical and thermal fatigue. These cracks can have different geometries and size.

Most suitable used Nickle based Electrode for this repair are “CeweldNICRO 600”( INCONEL 182 ) , Company Certilas , Holland . The following are the link

http://www.ceweld.com/en/product/inconel-182-e-nicro-600

We ( AHE) have experience of cracks repairing job on Kiln tyre and rollers . Recently, wehave repaired crack on kiln tyrein cherat cement , with welding electrode “CeweldNicro600” , In November 2018 .

Why Nicro 600 ( INCOLNEL 182) use

- Recommended for repairs on Nickle Alloy and heavy components

- Improved impact properties

- High crack resistance

- Easy to used in all positions

- Ideal for critical welding positions . Resistance to corrosion and high temperatures .

- Comparable Nicro 600 price is low .

- Reduce break down time .